Automatic adjustment of the length of the bamboo pole.

Automatic bamboo pole feeding.

Automatic detection of the outer diameter of the bamboo pole and the thickness of the entire circle of the bamboo pole.

Automatic splitter disc change.

Automatic bamboo splitting.

Automatic bamboo strip grading function

Demonstration Video On Youtube

I.Production Introduction

The fully automatic bamboo splitting and sorting machine developed by our company, and we have already applied for a number of national patents. It has fully automatic function that including:

1.Automatic adjustment of the length of the bamboo pole.

2.Automatic bamboo pole feeding.

3.Automatic detection of the outer diameter of the bamboo pole and the thickness of the entire circle of the bamboo pole.

4.Automatic splitter disc change.

5.Automatic bamboo splitting.

6.Automatic bamboo strip grading function

Our machine can help to reduces labor cost and improves efficiency. Compared with the traditional manual bamboo breaking machine, the automatic bamboo splitting machine can increase the output for customers, improve the quality of bamboo strips, and reduce the production cost at the same time.

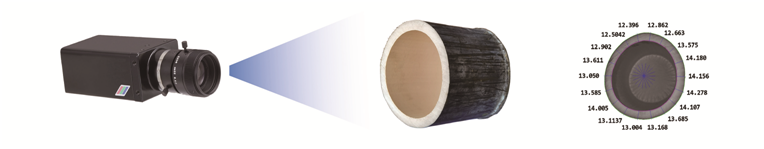

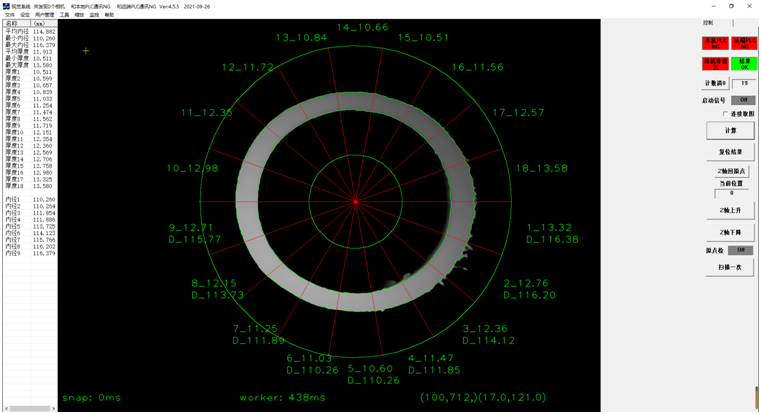

Our company take the lead of the visual camera measurement technology in the bamboo industry, using non-contact measurement methods to reduce measurement failures. The visual measurement can collect the thickness data of the whole circle of the bamboo tube to distinguish the each point surface, and the customer can choose any thickness according to the actual production.

The overall structure of the machine is welded by a square tube, with high rigidity, high strength and simple structure. The control panel is simple and intuitive, the equipment can be started by one button, and the running status and bamboo strip output are all recorded in the system, which is convenient to use.

2.Machining Specification

NO. | Description | Parameter |

1 | Total Installed Power | 18.5 KW |

2 | Machine Weight | Main Splitting Machine 3100KG Grading Machine 1700kg |

3 | Machine Size | 10450×9000×3300mm |

4 | Splitting Efficiency | Cycle time 6S-8S,as bamboo pole length difference |

5 | Quantity of Splitter Disc | 10 PCS |

6 | Bamboo Pole Length | 1000mm – 2600mm |

7 | Bamboo Pole Diameter | 50mm – 170mm |

8 | Quantity of Bamboo Strip Grading Trolley | 6-8 Units Trolley |

9 | Bamboo Pole Loading Direction | Left or Right, as per customer request |

10 | Length Adjusting | Automatic Parameter Setting |

11 | Splitter Head | Rotatable Head |

12 | Size Measurement | 3D Visual Technology, Whole Circle Thickness |

3. Machining Function

3D camera takes picture of bamboo pole to measure the size, by scanning the sawing surface of the bamboo pole to obtain the size data, the size accuracy can achieve 0.3mm and takes only 0.5 second. The size data including the thickness of the entire circle of the bamboo pole, and the inner & outer diameter of the bamboo pole.