Application

Oil & Gas

Aerospace

Heat Exchanger Plates (HEP)

Hydraulic & Pneumatic Components

Automotive & Vehicle Construction

Medical Technology

Shipbuilding

Power Plant

I. Introduction

Deep hole machining means machining of holes deeper than ten times the hole diameter. This can be done in different machine set-ups. The most common method is rotating the work piece while the tool is fed in a linear movement. Rotating tool is another option as well as a combination of the two.

Regardless of method, the basic principles of drilling still apply, and the correct choice of cutting speeds and feeds are crucial. Satisfactory chip breaking, and removing the chips from the cutting edge without damaging the tool or work piece, is essential. One of the most important success factors is an effective coolant system.

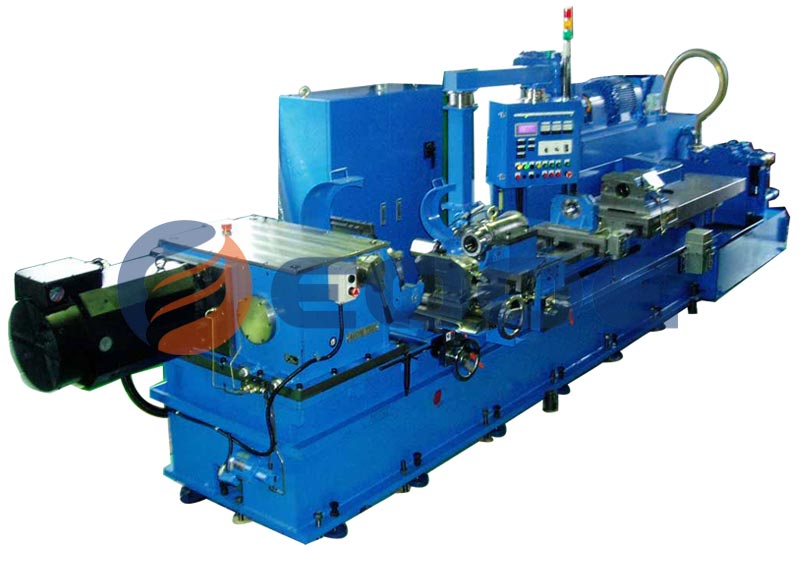

Deep hole drilling is generally performed on dedicated deep hole drilling machines which are manufactured and assembled to optimize the processes for straightness and efficiency. Advances in technology allow CNC machining centers, equipped with high pressure, through-spindle coolant, to be capable of gundrilling up to a limited depth-to-diameter ratio. UNISIG produces highly capable BTA and gundrilling machines, with applications exceeding 400:1 D:d ratios.

II. Specification

| Description | Specification |

| Drilling Diameter | Φ10mm – Φ80mm |

| Drilling Depth | 1000mm - 2000mm |

| Workpiece Diameter | Φ80mm – Φ200mm |

| Spindle Motor Power | 37kW - 45kW |