Produces super finish surface, with bore tolerance of IT7-IT8

Bore surfaces with Ra 0.05 to 0.2 micron finishes

One-pass process and double-pass process is optional

Surface hardness is increased by approximately 50% after roller burnishing

Demonstration Video On Youtube

I. Introduction

Hydraulic and pneumatic cylinders rely on ultra-smooth surface finish tolerances for operation longevity. The skiving and roller burnishing action passes over the material with skiving knives to create a perfectly round bore. This is followed by rollers that cold-work the surface and compress remaining material left behind from skiving, which creates a residual stress coating. The result is a supremely smooth interior wall with a mirror-like finish. When this process uses reliable machines such as those developed by TechniDrill, the end product extends the life of cylinders.

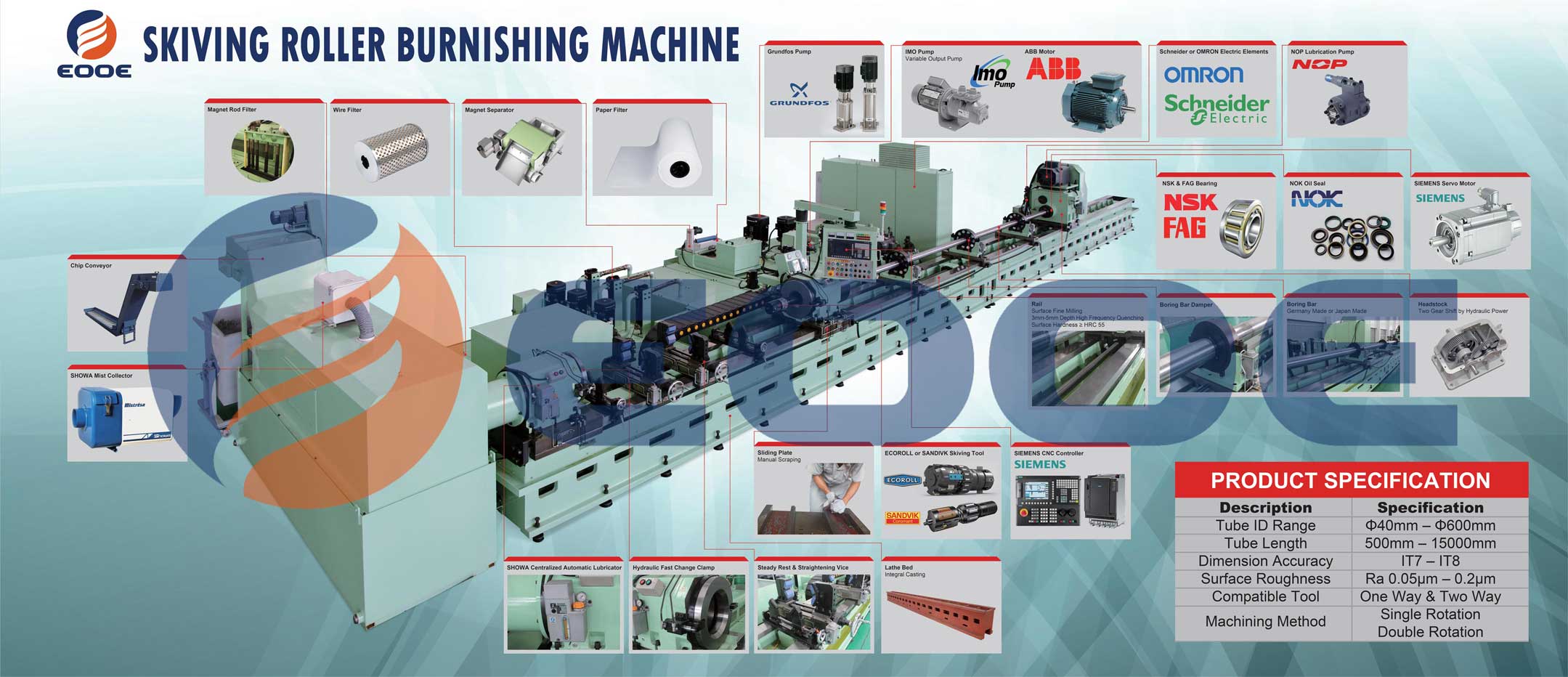

II. Specification

| Description | Specification |

| Tube ID Range | Φ40mm – Φ300mm |

| Tube Length Range | 500mm – 6000mm |

| Dimension Accuracy | IT7 – IT8 |

| Surface Roughness | Ra =0.03μm – 0.2μm |

| Compatible Tool | Single Pass / Double Pass |

| Tool Driving Method | Hydraulic / Pneumatic |

| Machining Mode | Single Rotation |

III. Components List

| Description | Supplier | Place of Origin |

| CNC Controller | SIEMENS | Germany |

| Main Shaft AC Motor | SIEMENS | Germany |

| Boring Bar Drive Motor | SIEMENS | Germany |

| Pressure Head Drive Motor | SIEMENS | Germany |

| Gear Box Bearing | NSK / FAG | Japan / Germany |

| Main Shaft Bearing | NSK / FAG | Japan / Germany |

| Rotation Connector | DEUBLIN | U.S.A |

| Cutting Fluid Pump | GRUNDFOS | Denmark |

| Pressure Switch | ACT | Japan |

| Lubricator Unit | SHOWA | Japan |

| Electronical Component | OMRON / SCHNEIDER | Japan / France |

| Electric Gauge | TOYO | Japan |

| Seal | NOK | Japan |

IV. Reference